Solar Inspections: Insights from a Solar Expert

Julia Guerra, a licensed drone pilot with extensive experience in oil and gas, sheds light on the transformative power of reality data capture technology in the solar farm industry. She walks us through the challenges faced in solar fields and the accessible solutions with reality data capture and then gives us a glimpse into the future of solar energy.

First, a little history lesson

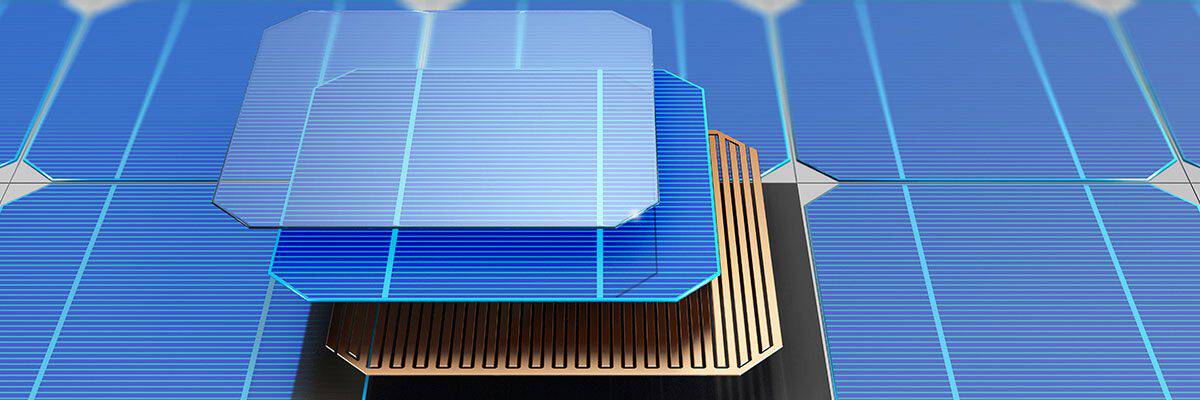

The journey of solar panels began in the mid-19th century, with the discovery of the photovoltaic effect by French physicist Edmond Becquerel in 1839. This groundbreaking discovery laid the foundational stone for solar energy conversion. However, it wasn’t until 1954 that Bell Labs in the United States pioneered the first practical silicon solar cell, marking the inception of modern solar power technology. Over the decades, solar panels have evolved from a niche scientific curiosity to a worldwide cornerstone of renewable energy initiatives. Their capacity to convert sunlight directly into electricity using semiconductors revolutionized how we harness solar energy, offering a sustainable alternative to fossil fuels.

The Backbone of Solar Efficiency

As the deployment of solar panels grew, the need for meticulous maintenance and efficiency optimization became paramount. Solar inspections are critical to ensure solar panel systems operate at peak performance. “Initially, solar inspections were predominantly manual and labor-intensive,” Julia explains. “They relied on visual assessments and basic electrical testing conducted by technicians on-site.”

These early methods involved physical inspections for visible defects such as cracks, soiling, or any obstructions that could affect the panel’s performance. Julia continues, “Technicians used handheld devices to measure electrical output and identify underperforming or malfunctioning panels.”

Despite its straightforward nature, this approach was fraught with challenges. “It was time-consuming, especially for large installations,” Julia says. “There were safety risks to inspectors who had to navigate difficult terrains or heights.” Moreover, the accuracy of these inspections was heavily reliant on the inspector’s expertise and could miss subtle defects not visible to the naked eye.

The drive towards more efficient solar panel inspections was fueled by the burgeoning demand for renewable energy and the rapid expansion of solar farms. As installations grew in size and complexity, the limitations of manual inspections became increasingly apparent, including navigating the extensive horizontal layouts of solar fields, which limited inspection scope to a mere fraction of the total area. “Inspecting three percent of a solar farm was basically the norm,” Julia admits. “But to ensure optimal performance and longevity of the installations, inspections needed to be more accurate, safe and efficient.”

Enter Drone Technology and Reality Data Capture for Solar Inspections

This necessity sparked innovation, leading to the adoption of advanced technologies such as thermal imaging, photovoltaic testing equipment, and drone-assisted inspections. These advancements have significantly improved the ability to detect various issues, from thermal hotspots indicating electrical faults to subtle shading effects, with greater speed and less risk to human inspectors. By addressing the challenges of early inspection methods, these technologies have played a pivotal role in maintaining the reliability and efficiency of solar energy systems, thereby supporting the global transition to sustainable energy sources.

“Now, thanks to advancements in drone technology, we’re not just aiming for 100% coverage,” Julia tells us. “We’re achieving it.” This leap from manual, time-consuming processes to comprehensive, efficient inspections marks a significant milestone in the solar industry’s evolution.

Diving into Thermal Imaging and RTK

The practical applications of drones equipped with thermal imaging and Real-Time Kinematic (RTK) positioning have indeed become central to revolutionizing solar inspections. The integration of these advanced technologies allows for a comprehensive and detailed analysis of solar panel installations from an aerial perspective, offering previously unattainable insights with ground-based inspections alone. Julia explains, “Thermal imaging cameras mounted on drones can swiftly identify hotspots and anomalies in solar panels, which indicate potential issues like electrical faults, defective cells, or poor connections. This capability is invaluable for preventive maintenance, ensuring that any efficiency losses are addressed promptly before leading to significant power generation declines.”

Furthermore, the addition of RTK positioning enhances the accuracy and reliability of drone inspections. RTK systems utilize GPS and fixed ground-based reference stations to provide centimeter-level positioning accuracy. This precision is crucial for detailed mapping and inspection of solar farms, enabling drones to navigate and cover vast areas methodically and with pinpoint accuracy. “As a result, every panel is thoroughly inspected, and the data collected are of the highest fidelity, ensuring no defect goes unnoticed.”

By leveraging these sophisticated tools, the commissioning process of solar panel installations is significantly improved. “Stakeholders can now monitor and validate the installation and performance of solar farms with better efficiency and precision than ever.” Julia continues, “The data captured by drones equipped with thermal imaging and RTK positioning are easily integrated into digital platforms, facilitating real-time analysis and long-term monitoring, which supports proactive maintenance strategies and optimizes the performance and lifespan of solar installations.”

Besides accelerating inspection times, this method allows for rapid scalability and deployment of solar energy resources. It also mitigates the risks of traditional manual inspections, which often involve personnel navigating challenging terrains or working at heights, exposing them to potential accidents.

Ultimately, applying these technologies underscores a transformative shift towards more sustainable, efficient, and safer practices in the solar energy industry, paving the way for a cleaner, more resilient energy future.

A Glimpse into Industry Impact

Implementing thermal imaging benefits the ground teams in terms of efficiency and safety and streamlines the entire production cycle of solar fields. Ground personnel can rely on data captured to pinpoint specific areas of concern, allowing teams to focus on targeted maintenance and repair efforts. Consequently, this leads to a more efficient allocation of resources and a significant reduction in downtime for solar installations.

“From initial installation to ongoing maintenance, drones offer a continuous feedback loop of data, enabling solar companies to perform in-house quality assurance checks with a high level of detail.” Julia explains that reality data capture integrates seamlessly into solar software that transforms raw data into actionable commissioning maps, offering a 4D view of each panel. This advancement enables detailed analysis and asset tracking, revolutionizing how stakeholders interact with inspection data. “Before the final handover of a project, stakeholders can ensure that every panel, connection, and component meets the highest performance and reliability standards.”

For clients, this translates to a higher standard of delivery. Reality data capture for solar panel inspections is completed more swiftly and is also of superior quality, with minimized risks of post-installation issues. “This quality assurance process builds trust and satisfaction among clients, establishing a strong foundation for long-term relationships.” Additionally, consistently delivering projects that meet or exceed expectations reinforces a company’s reputation in the competitive renewable energy market.

The Path Forward: Trends and Developments

Julia is optimistic about the future of solar panel inspections, emphasizing the revolutionary impact of autonomous drone technology. “With drone docks, we’re stepping into an era where drones autonomously perform monthly inspections, identifying issues without human intervention. This is a significant leap forward in solar energy management,” she states. Thanks to advancements in drone battery technology and AI analytics, Julia envisions these drones as part of a smart system capable of extensive area coverage and precise anomaly detection.

“The transition to autonomous inspections is not just about efficiency; it’s about scaling our capabilities and minimizing environmental impact,” Julia adds, highlighting the dual benefits of operational efficiency and sustainability. She believes this technology aligns with the solar industry’s growth and sustainability goals, reducing manual labor and enhancing the reliability of solar installations.

Julia sees autonomous drone inspections as a transformative development for the solar industry. They offer a scalable, efficient, and environmentally friendly approach to maintaining and optimizing solar energy systems. This innovation promises to redefine renewable energy management with its precision, efficiency, and commitment to sustainability.