Why Thermal Imaging is Critical for Accurate Flare Stack Inspections

Flare stacks are essential to industrial operations, particularly in the oil and gas sector. They play a crucial role in safely burning off excess gasses, ensuring operational efficiency and environmental compliance. However, maintaining the integrity of flare stacks through regular inspections is critical to preventing potential hazards. Traditional inspection methods of these towering structures often come with challenges, including limited access and safety risks. This is where thermal imaging technology steps in, revolutionizing the way flare stack inspections are conducted. This blog explores the vital role of thermal imaging in enhancing the accuracy, efficiency, and safety of flare stack inspections.

The Importance of Flare Stack Inspections

Flare stacks serve as safety devices in industrial facilities, burning off flammable gasses that cannot be recovered or recycled. Ensuring operational integrity is paramount, as any malfunction can lead to significant safety risks, environmental damage, and regulatory non-compliance. Regular inspections are necessary to identify and resolve issues before they escalate into major problems. However, the complexity and height of flare stacks make these inspections challenging, particularly when using traditional methods. Traditional inspection methods often fail to provide comprehensive data, especially when detecting hidden issues.

Regular Flare Stack inspections are essential to:

- Prevent environmental hazards

- Ensure regulatory compliance

- Maintain operational efficiency

- Identify potential safety risks

Challenges in Traditional Flare Stack Inspections

Inspecting flare stacks has traditionally been a labor-intensive and risky process. Physical access to these structures often requires scaffolding or cranes, exposing personnel to significant safety hazards. Moreover, visual and manual inspections have limitations in detecting internal issues or subtle heat anomalies that could indicate potential failures. These methods are time-consuming and less accurate, leading to a higher risk of overlooking critical matters.

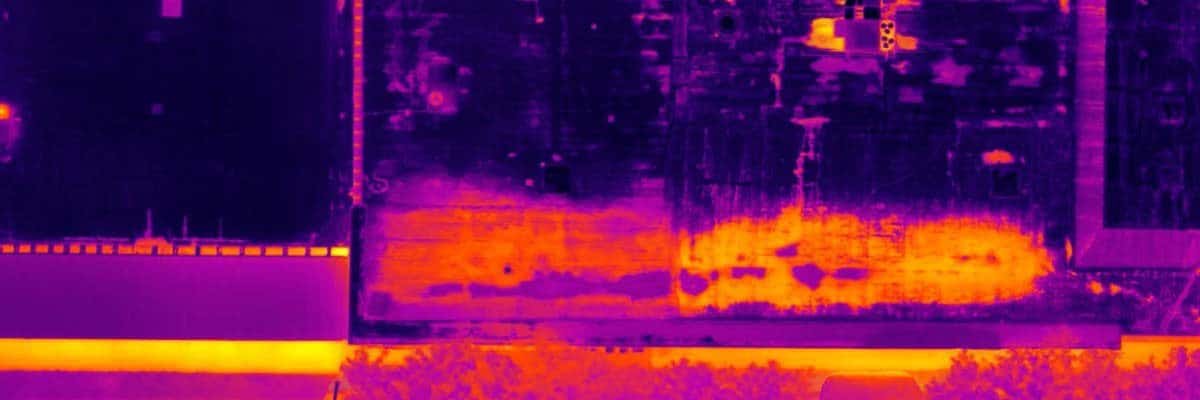

How Drone-Mounted Thermal Imaging Enhances Flare Stack Inspections

Since the early 2000s, flare stack inspections have utilized thermal imaging. The adoption of this technology was driven by the need for safer, more efficient, and more accurate inspection methods in the oil and gas industry. Initially, thermal imaging was conducted with handheld cameras and mounted on platforms like helicopters to inspect hard-to-reach areas. However, the significant integration of thermal imaging in flare stack inspections gained momentum with the advancements in drone technology around the 2010s.

The combination of drones and thermal cameras allowed for safer, quicker, and more detailed inspections of flare stacks, which further solidified thermal imaging as a crucial tool in this field. As technology continued to improve, the resolution, range, and accuracy of thermal imaging systems also enhanced, making them an indispensable asset in flare stack inspections today.

Key benefits of drone-mounted thermal imaging include:

- Non-Contact Inspection: Thermal cameras on drones capture detailed images from a safe distance, eliminating the need for dangerous close-up inspections.

- Early Problem Detection: Thermal imaging identifies hot spots or unusual temperature patterns, revealing issues like refractory damage, pilot flame problems, gas leaks, and inefficient combustion.

- Comprehensive Data Collection: It provides a complete temperature profile of the flare stack, offering insights into flame characteristics, heat distribution, and insulation effectiveness.

- Real-Time Monitoring: Drones allow real-time surveys of operational flare stacks, capturing dynamic temperature data during actual flaring events.

Real-World Applications

Several companies in the oil and gas industry have successfully implemented thermal imaging for flare stack inspections, experiencing significant improvements in accuracy and safety. For instance, a leading energy company reduced its inspection times by 50% and lowered costs using thermal imaging technology. The ability to detect issues early has also minimized downtime, further enhancing operational efficiency.

In addition to cost and time savings, thermal imaging has improved the overall safety of inspections. By reducing the need for personnel to access high-risk areas, the likelihood of accidents has decreased, making inspections safer for everyone involved.

Enhancing Inspection Accuracy and Efficiency

- Reduced Downtime: Thermal inspections can often be conducted without shutting down operations, minimizing costly production interruptions.

- Improved Safety: By reducing the need for close-up manual inspections, thermal imaging enhances worker safety.

- Predictive Maintenance: Regular thermal surveys help identify developing issues before they become critical, enabling proactive maintenance scheduling.

- Cost-Effective: While the initial investment in thermal imaging equipment may be significant, the long-term benefits of preventing failures and optimizing operations outweigh the costs.

Future of Flare Stack Inspections with Thermal Imaging

As thermal imaging technology advances, its applications in flare stack inspections are expected to grow. Integrating thermal imaging with UAVs and artificial intelligence (AI) further enhances the accuracy and efficiency of inspections. These advancements will allow for even more detailed and comprehensive assessments of flare stacks, ensuring that potential issues are detected and addressed before they become critical.

Industry trends indicate a growing adoption of thermal imaging across the oil and gas sector. As regulatory requirements become more stringent, the ability to conduct thorough and accurate inspections using thermal imaging will be essential for maintaining compliance and protecting the environment.

The Cost-Effectiveness of Partnering with a Reality Data Capture Tech Company

Partnering with a reality data capture technology company that offers access to drone-mounted thermal imaging can be a highly cost-effective solution for flare stack inspections. These companies bring the latest technology, skilled pilots, and expertise to conduct precise inspections without the significant investment in equipment and training. Outsourcing to a data capture provider not only saves time and reduces risks but also ensures that inspections are performed with the highest standards of accuracy and safety.