ROCKing With our new LiDAR Sensor

We are excited to reveal our new relationship with ROCK Robotic.

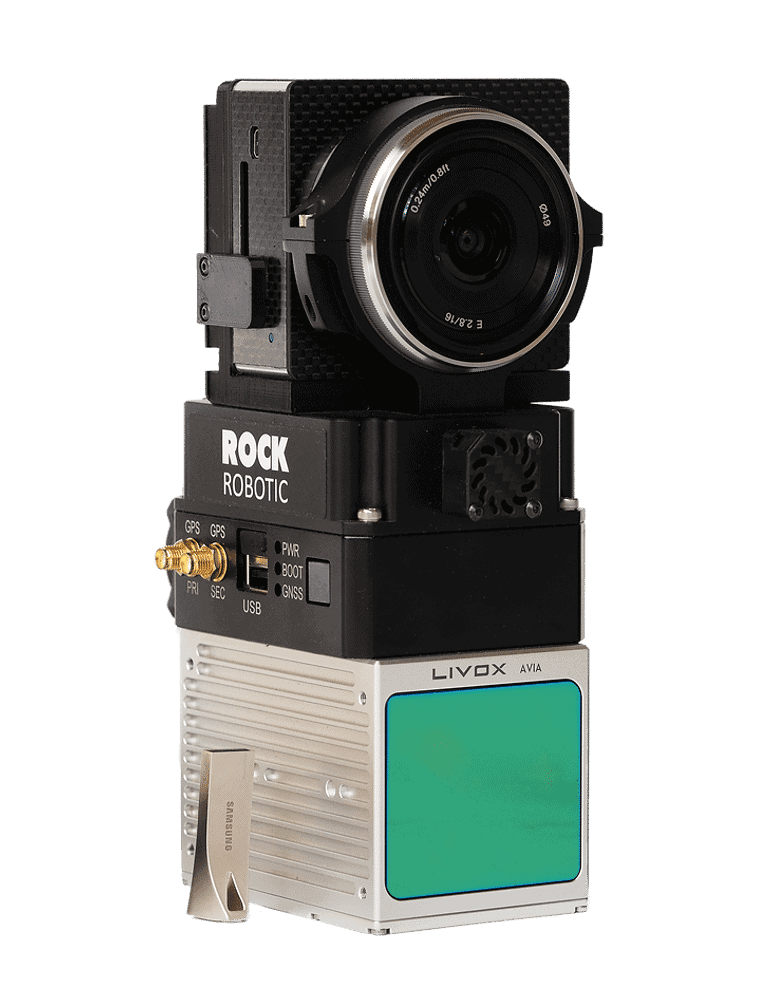

A few months ago, we were introduced to startup LiDAR company ROCK Robotic, which offers a complete aerial mapping solution. We happened to be on the prowl for a new LiDAR sensor, so our ears perked up when we heard about founders Harrison and Alex Knoll’s LiDAR software company. ROCK Robotic checked many of the boxes in our search for a way to scale our LiDAR division at an affordable price.

The brothers’ LiDAR solutions platform promises to build a strong LiDAR community rooted in unparalleled support, and we can honestly vouch that they are doing just that.

Since we started offering LiDAR services, we have had the opportunity to experiment with different sensors, and over the years, we have been able to narrow in on the primary needs of our clients. So, choosing to partner with ROCK Robotic seemed natural for us.

Why we switched to R2A

Ninety-five percent of our use cases are collecting data for surveyors to develop one-foot contour files, so we need to maintain a range of two to five centimeters to deliver high-resolution results. Our previous sensors have been highly accurate, down to two centimeters. But with this accuracy comes a high price tag.

In walks ROCK Robotic’s R2A sensor with the accuracy we need to deliver one-foot contour lines…at half the price. When the question becomes accuracy vs. price (and we are talking $140k-240k difference), the answer is a no-brainer. The R2A delivers the results we need for the majority of our clients, and we can’t pass on the lower price point.

It’s a win-win-win for us, ROCK Robotic, and our clients!

What’s more, the R2A has solved our issues with quality assurance/quality control (QAQC) in the field. We experienced some technical difficulties in the processing stages with our previous sensors. Even though the sensor was highly accurate, the point density was relatively low, making it difficult to accurately depict the center point of targets. The R2A sensor has effectively tripled our point density.

Improved Deliverables

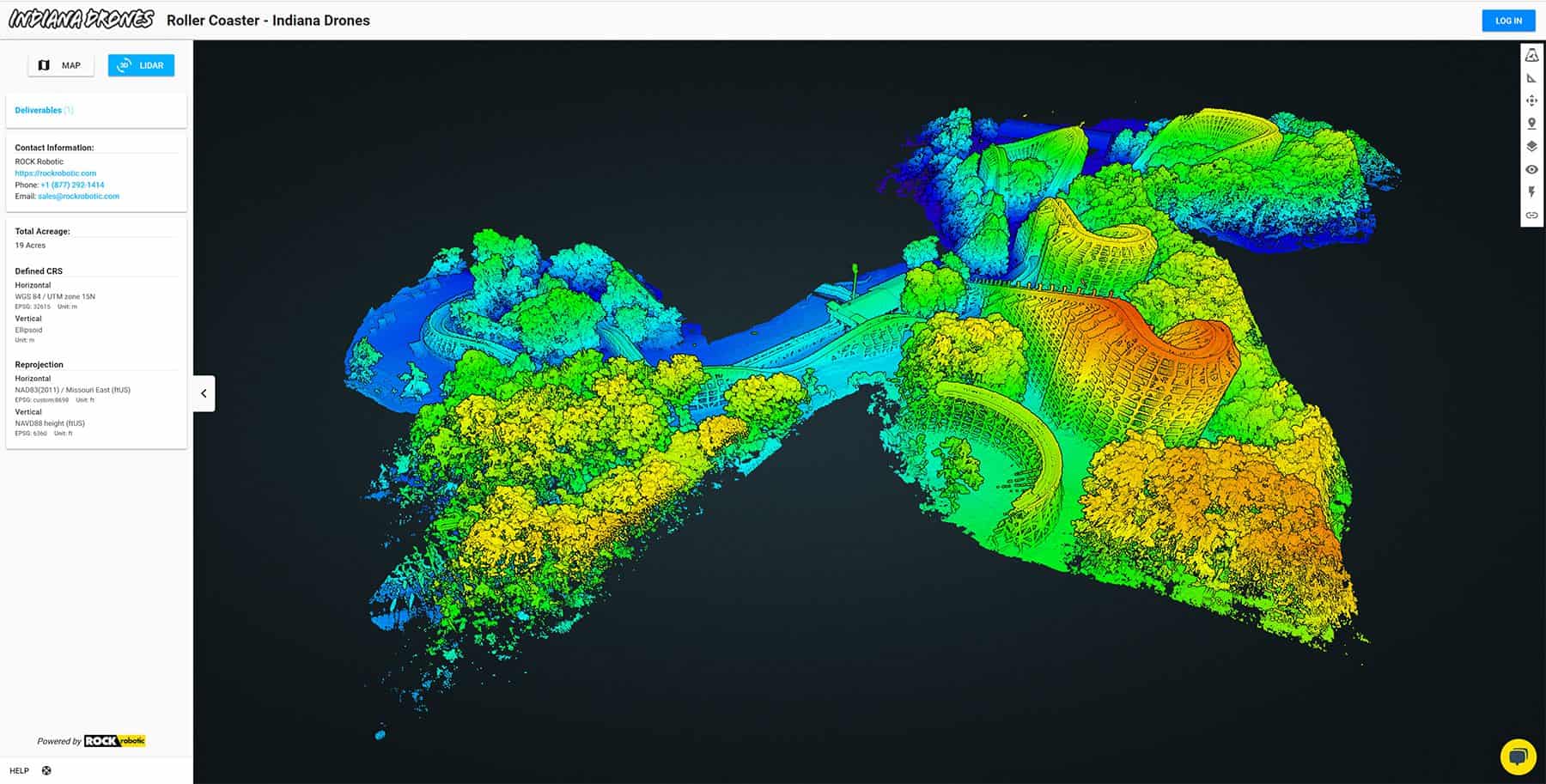

ROCK Robotic R2A sensor has been a game-changer for our LiDAR deliverables, but it doesn’t stop there. The startup also offers online data hosting. All data from the R2A is organically processed in WSG84 ellipsoidal height, so we use their platform to reproject the data to NAD83 (2011) sate plane geoidal height, which is the datum used by most of our clients.

ROCK Robotic’s cloud-based platform offers a variety of deliverables, and while we do most of our processing in-house, we have seen success using their platform to generate planimetrics.

ROCK vs. Reigl

We conducted our own case study- Reigl vs. ROCK, and we found that the data was remarkably similar. The ROCK data falls within the guidelines of providing one-foot contours, our bread and butter. So it only made sense to cut our costs and increase our efficiency in the field. The R2A has a lighter payload allowing us to upgrade from an M600 to an M300 and increase the number of flights we can perform in one day.

The future with R2A

Given the success we have already seen with the R2A, we are excited to purchase more sensors from ROCK Robotic to expand our LiDAR services to our clients.

The LiDAR world can be challenging to navigate. Unfortunately, many of those who work in LiDAR are set in their ways and tend to operate from an outdated point of view. From traditional surveying to LiDAR experts, it is not out of the ordinary to hold tight to legacy technologies. ROCK Robotic is breaking the mold to educate and make LiDAR easier from a usability standpoint. Together, we will revolutionize how LiDAR data is captured by removing the more complicated aspects of the technology.